Simple QA Checklists That Reduce Callbacks for Field Technicians

.webp)

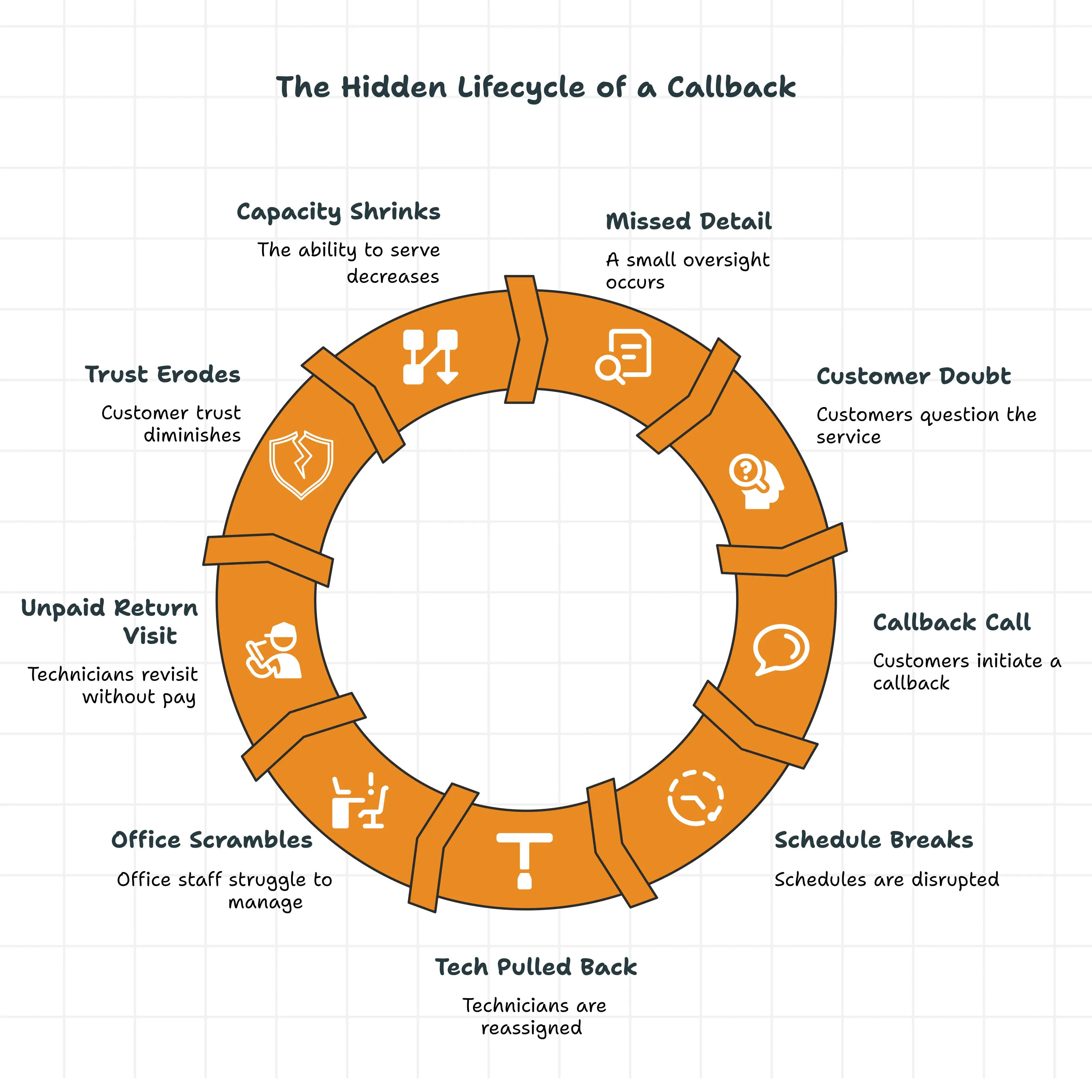

Callbacks are a big problem for any service business. Your technician finishes a job, packs up, and leaves. Then the phone rings. It’s the customer, and they’re not happy. The AC isn’t cooling. The faucet is still dripping.

Now you have to pull a tech off a paying job to fix work you’ve already billed for. That’s lost revenue, a trashed schedule, and damage to your reputation. It’s frustrating for everyone. And in an industry this big, the stakes are high. The global field service management market was valued at USD 4.43 billion in 2022 and is projected to reach USD 11.78 billion by 2030. With a growth rate of 13.3%, there is no room for sloppy work.

But here’s the thing: most callbacks aren’t caused by major disasters. They happen because of the small stuff. A skipped step. A loose connection. A detail buried in a manual nobody read.

Field service work is messy. Your team is moving fast and working against the clock. Even your best people can miss something when they’re rushed. Relying on memory isn’t a system.

Enter the humble QA checklist. It’s not flashy, but it’s the secret weapon against callback chaos. A simple list brings consistency and clarity to every job. And when you move those checklists from paper to a digital tool, things improve even more.

How Simple QA Checklists Reduce Callbacks

Most callbacks occur in the gap between “almost done” and “truly finished.” A good checklist helps close this gap:

-

It doesn’t overload technicians with unnecessary steps.

-

It provides clear direction from start to finish.

-

It focuses attention on critical steps during the last few minutes of a job, when fatigue and customer presence can lead to mistakes.

Think of QA checklists as a safety net. They guide technicians to double-check their work before calling a job complete. It’s not micromanaging. It’s building a reliable workflow that saves time and money.

Digital checklists take it a step further. With tools like Field Promax, technicians complete everything on their mobile devices. No more lost paper. Everyone follows the same process, and management gets instant visibility.

When you reduce mistakes, you cut down on callbacks. Fewer callbacks mean happier customers, lower costs, and more repeat business. It’s a simple change that delivers big results.

1. Turning Ordinary Steps into Habits

You brush your teeth every morning (hopefully). You don’t need a sticky note on the mirror to remind you. It’s a habit. That’s what we want for your technicians' safety and quality checks.

Routine checks become second nature when they are part of a mandatory workflow. When a technician sees the same four prompts on every single job, they stop thinking about whether they should do them and just do them.

-

Verify all connections.

-

Test equipment when not in use.

-

Confirm readings or measurements.

-

Ensure all safety requirements are addressed.

At first, they might roll their eyes. "I know how to do my job," they'll say. But after a week, it becomes muscle memory. Those prompts stop being annoying and start being the guidelines that prevent small issues from turning into expensive callbacks.

2. Setting Up a Clear “Last Look” Before Leaving the Site

A simple pause at the end of a job can go a long way in ensuring quality and customer satisfaction. This quick review process helps technicians catch any potential issues before leaving the site. Here's how:

-

Test the system with the customer present. This not only confirms that everything is in working order but also reassures the customer of the quality of service.

-

Take an accurate photo of the completed setup. This serves as a documented record of the work done and can be shared with the office or used for future reference.

-

Note any risks, follow-up items, or suggestions. Identifying potential concerns or recommending maintenance builds trust with the customer and demonstrates professionalism.

By incorporating this simple review routine, technicians can ensure that all details are addressed, leaving no room for miscommunication or oversights once they are off-site.

3. Supporting Newer Technicians Without Constant Supervision

Checklists are an invaluable tool for guiding newer technicians, reducing their dependency on memorization, and empowering them to learn workflows more effectively. Here’s how they help:

-

They reduce dependency on memorization. Newer technicians can follow structured steps rather than relying on experience or guesswork.

-

Technicians can focus on learning the workflow. Instead of worrying about missing steps, they can concentrate on mastering their tasks.

-

Managers gain peace of mind, knowing steps are documented and followed. This eliminates the need for constant oversight, freeing up time for higher-level tasks.

Checklists act as a "silent guide," offering clear instructions while building confidence and ensuring consistent quality across the team.

4. Making Quality Visible for the Office Team

A properly filled-out checklist does more than just confirm task completion; it drives accountability and creates opportunities for improvement. Here's how checklists elevate the entire team's quality system:

-

They show what was done, when, and by whom. This record keeps everyone informed and fosters transparency.

-

Patterns of recurring issues become visible. By analyzing completed checklists, managers can identify frequent challenges or bottlenecks.

-

Adjustments to training and procedures are easier. With clear data, leaders can adapt processes to address recurring issues and improve overall efficiency.

Over time, checklists evolve from a simple task-tracking tool to a dynamic quality system ensuring tighter operations, consistent training, and visibility for the entire team.

Why Digital Checklists Work Better Than Paper?

Paper checklists have limitations: they get crumpled, lost, or filled out in a hurry. Digital checklists efficiently solve these problems and offer additional benefits that paper simply cannot match:

1. Always With the Technician

Technicians already have their phones out. Why add a clipboard to the juggle? Digital checklists live right on their devices, making it easy to snap photos, leave notes, and check boxes in real time. No more "I’ll do it later" excuses, just accurate data and fewer mistakes. It’s about letting your team focus on the job, not the paperwork.

2. Easier to Adjust as Work Changes

Fieldwork changes fast. Equipment evolves, safety rules shift, and processes pivot. Why stay stuck with static paper? Digital checklists update instantly for everyone. Add a step, tweak a protocol, or scrap an old rule without touching a printer. It keeps your team on the same page and always ready for what’s next. No more outdated instructions, just pure, flexible efficiency.

3. Better Visibility for the Office Team

Perhaps the biggest advantage is better visibility. Office staff can track job progress in real-time, spot recurring problems, and proactively help technicians. This data also helps target training, fine-tune processes, and improve customer service. Digital checklists are more than task trackers; they're a tool for smarter decisions.

By switching to digital, you streamline workflows, improve accuracy, and make your operations more efficient.

What a Simple QA Checklist Should Include?

Effective quality assurance (QA) checklists should be seamlessly designed to integrate naturally into the technician's workflow rather than feel like an extra task. A simple, well-structured checklist helps minimize errors, improve customer satisfaction, and ensure consistent results. The flow typically follows these key phases:

1. Pre-Job Checks

-

Confirm the work order details, site address, and customer notes are accurate.

-

Verify the availability of required parts and tools.

-

Ensure all safety requirements are met and understood.

-

Confirm access information, such as codes, keys, or contact details.

2. Task-Specific Steps

This part of the checklist should include clear, concise instructions for the specific job at hand, whether it's an installation, a repair, or routine maintenance. By using scannable steps, technicians can easily follow along and check off completed tasks, avoiding unnecessary confusion.

3. Last Steps of Quality Control

-

Perform functional tests to ensure everything is operating correctly.

-

Inspect for any leaks, unusual noises, or alerts that may indicate issues.

-

Secure all panels, covers, or other components.

-

Clean up the work area, leaving it neat and safe for the customer.

4. Documentation and Evidence

-

Take photos of the completed installation or repair to serve as a visual record.

-

Log readings, measurements, or dimensions for critical components.

-

Document risks, follow-up requirements, or additional parts used to keep records accurate and actionable.

5. Handoff and Customer Communication

-

Explain the work completed in simple, layman's terms that the customer can easily understand.

-

If applicable, demonstrate how to use the system or feature you’ve installed or repaired.

-

Confirm the customer is satisfied with the work, leaving on a positive and professional note.

By including these elements in a QA checklist, you ensure every task is completed accurately, any risks or issues are documented, and the customer feels confident in the service provided. This structured approach ensures consistency and builds trust, no matter the technician or the job.

.webp)

Leveraging Customer Feedback to Strengthen QA

Customer feedback is a critical, yet often underutilized, tool in improving QA processes. By actively gathering and leveraging insights from customers, field service businesses can drive continuous improvement across their workflows. Here's how:

-

Capture real-world insights: Customers can often identify small issues or oversights that might escape the eyes of even the most experienced technicians. Listening to this feedback ensures a more thorough and effective service.

-

Refine checklist items: Feedback can point out recurring gaps or inefficiencies in existing processes, enabling you to update QA checklists for better accuracy and relevance.

-

Strengthen trust: When customers feel that their input is valued and acted upon, callbacks transform from mere complaints to meaningful opportunities for learning and growth.

Example: Imagine a customer reporting that while their HVAC system was fixed and functional, they struggled to understand the controls. By adding a specific checklist step to confirm the customer's understanding of the system before leaving, such issues can be proactively avoided in future jobs.

Continuous Improvement Through Data-Driven Insights

QA checklists, when used consistently, are more than just task reminders – they are powerful tools for generating actionable data that can guide improvements. Consider these advantages:

-

Track patterns: Analyze data from completed jobs to identify recurring steps where errors or oversights are most common.

-

Optimize workflows: Use the insights to adjust the sequence or detail of checklist items, making them clearer and more effective for technicians.

-

Support training: Identify specific areas where technicians struggle and design targeted coaching to address these gaps.

-

Predict problems: Use historical data to anticipate recurring issues and resolve them proactively before they escalate.

Digital tools and online form builders make this easy.

Analytics dashboards show you where things are going wrong. They spot recurring mistakes and highlight where workflows can improve. This makes it simple to see where technicians need more training or where processes need an upgrade.

It’s data-driven improvement, made simple.

Integrating QA Checklists With Workflow Management Systems

Checklists work best when they are part of a broader workflow, not isolated steps. By integrating quality assurance (QA) checklists with workflow management systems, businesses can achieve smoother operations, greater accountability, and enhanced service quality. Here’s how:

1. Seamless Job Tracking

-

Integrating QA steps into task management systems ensures technicians follow the correct sequence.

-

Checklists align with workflow milestones: pre-job inspections, active task evaluations, and post-job reviews.

-

Reduces the risk of skipped steps, even in high-pressure situations.

-

Notifications and prompts ensure nothing is overlooked, maintaining consistent service standards.

2. Real-Time Status Updates

-

Real-time updates for everyone involved. What’s not to love?

-

Office staff see what's done and what's verified. No more guessing games.

-

Supervisors get a bird's-eye view, stepping in only when needed.

-

Customers get transparent updates. And that builds trust.

3. Reducing Rework Through Automated Feedback

- Stop the Guessing Game

Linking QA data to your workflow makes bottlenecks and repeat errors impossible to hide. It's like having a second pair of eyes that never gets tired.

- Catch It Before It Costs You

Automated alerts flag careless work or missed steps instantly. Catching a mistake now means one less expensive callback later.

- Quality on Autopilot

When QA is built into the process, it is not an extra task. It becomes part of daily work.

- Trust Is the Ultimate Goal

Reliable work leads to happy customers. And happy customers lead to repeat business. Simple as that.

Future-Proofing QA Practices for Scaling Teams

As a field service team grows, maintaining consistent quality can become challenging. However, leveraging simple QA checklists and digital tools ensures that your team can scale efficiently without compromising standards. Here’s how:

1. Standardized Training for New Technicians

New hires shouldn't have to guess what "good" looks like. Standardized checklists act as a roadmap, cutting out the need for constant babysitting. Whether you're across town or across the state, every tech follows the same playbook. It’s the easiest way to ensure top-tier service from the very first day.

2. Adapting to Complex Equipment and Services

As your team tackles advanced tech, dynamic checklists and digital QA tools keep everyone updated. With multimedia instructions like videos and diagrams, your team is always ready to get the job done.

3. Building a Culture of Continuous Improvement

QA checklist data provides actionable insights to address recurring issues and drive measurable improvements. Quality becomes a visible, repeatable process that evolves with your business and is embraced by your entire team.

4. Scalable Documentation and Proof of Quality

Every completed checklist creates a solid paper trail. As you scale, digital archives keep you compliant and accountable without the headache. Plus, customers love seeing the same top-tier results every single time, no matter how big you grow.

By weaving QA practices directly into your team’s DNA, you’re doing more than just preparing for growth; you're future-proofing your business. Consistent quality at scale shouldn’t feel like a chore. With Testpad, it becomes second nature. It’s not just a tool; it’s simply how your team gets the job done right.

Maximizing the ROI of QA Checklists

The true value of QA checklists is realized when the:

-

Prevent callbacks: Technicians leave jobs completed correctly the first time.

-

Support training: New staff ramp up faster with less direct supervision.

-

Enable data-driven decisions: Teams can refine processes based on real-world performance.

-

Enhance customer satisfaction: Clear communication and visible quality reduce confusion and complaints.

-

Scale efficiently: As the team grows, checklists maintain quality without adding complexity.

By combining simple QA checklists, digital tools, and integrated workflows, service organizations can create a continuous loop of quality improvement: plan → execute → document → review → improve.

It's a straightforward approach that keeps everyone aligned, ensures consistent results, and drives long-term success without added trouble.

Conclusion

Reduced callbacks don’t happen by accident. They’re the result of small, consistent habits.

-

Guide technicians without slowing them down.

-

Use digital tools to keep instructions, schedules, and data accurate.

-

Create clear documentation for feedback and training.

-

Integrate QA into workflows with tools like Field Promax to scale quality across the team.

When systems are simple and expectations are clear, callbacks fade. Trust grows. And quality becomes something you can count on every time.