Top Features to Seek in a Pump Controller for Efficient Water Resource Management

Whether it’s in mining, construction, agriculture, or aquaculture, pump controllers have always been a vital part of various industrial-level operations.

According to a research, the global smart pump system market is projected to reach $8.7 billion by 2030, growing at a CAGR of 6.4%. This growth underscores the increasing reliance on pump controllers across industries to save water, energy, and time.

A pump controller is a crucial component for automating the operation of water pumps. It can start or stop the pump based on water levels, adjust the flow to meet demand, and send alerts to site managers via an accompanying app should there be issues like low water pressure or excessive water levels, making it a must for effective water resource control. This level of automation saves labour, reduces energy use, and helps protect both the equipment and the site from water-related issues.

If your site is in need of a pump controller, then it’s important to choose one with the right features to ensure it’ll get the job done well. Here are some key features that a pump controller should definitely have for efficient water resource management.

1. Automated Start-Stop Control

An automated start-stop feature is what enables pump controllers to manage water levels without needing constant human intervention. This function allows the pump controller to activate or deactivate the pump when water reaches a specific level or when the level drops. Thus, you can rest assured that your sites won’t encounter overflows and dry running (a phenomenon when a pump can’t operate properly as it doesn’t have sufficient liquid or lubricant to do so). For projects such as mining and construction where water inflow can sometimes be unpredictable, automated start-stop controls ensure reliable and efficient water management. You can also incorporate IoT water utility alongside pump controllers to enhance water management.

2. Remote Monitoring and Control

Having the means to remotely access your pump controllers is also a must. This feature is especially useful for site managers in charge of large-scale projects, as checking on each pump positioned all over the site can be challenging and time-consuming. With a remote-controlled and monitored pump controller, you can easily check on water flow rates and pump system status through a software or app through your desktop computer or smartphone.

Additionally, a remote pump controller allows you to grant different access levels to your staff as needed. This gives you the assurance that only authorised individuals are able to access and operate the pumps, which strengthens the security of your operations.

3. High and Low Water Level Alarms

Another important feature for a pump controller are high and low water level alarms. These alarms can notify you if water levels exceed or drop below predetermined limits, allowing you to swiftly take any action needed to stabilise it. These features can also help mitigate flooding and water shortages that can disrupt operations or cause damage to your equipment. Ideally, you should be able to receive notifications from these alarms through the pump controller’s accompanying software or app so you can respond accordingly even without going to the pump’s location to check.

4. Built-In Pressure and Flow Sensors

Pump controllers that come with integrated pressure and flow sensors allow for more accurate adjustments of pumping operations to maintain optimal water flow and pressure. If your project is prone to fluctuating water demands, then this feature is a must for efficiency and to avoid pump damage like cavitation (the formation of bubbles or vapour pockets on the pump’s components due to varying pressures). Pressure and flow sensors ensure consistent water delivery and help reduce stress and wear on your equipment, thus preventing costly repairs and replacements down the line.

5. Data Logging and Reporting

Monitoring key metrics about pump performance such as runtime, flow rates, and energy usage over time is helpful in identifying any inefficiencies in your water resource management approach. The data gathered can be used to stay proactive in scheduling maintenance to prevent downtime. It can also guide you in budgeting operation costs; when you have accurate data, you can optimise pump settings to reduce energy consumption and conserve water resources. Thus, make sure your pump controller is able to accurately keep track of pump performance records and generate detailed reports that you can review at any time.

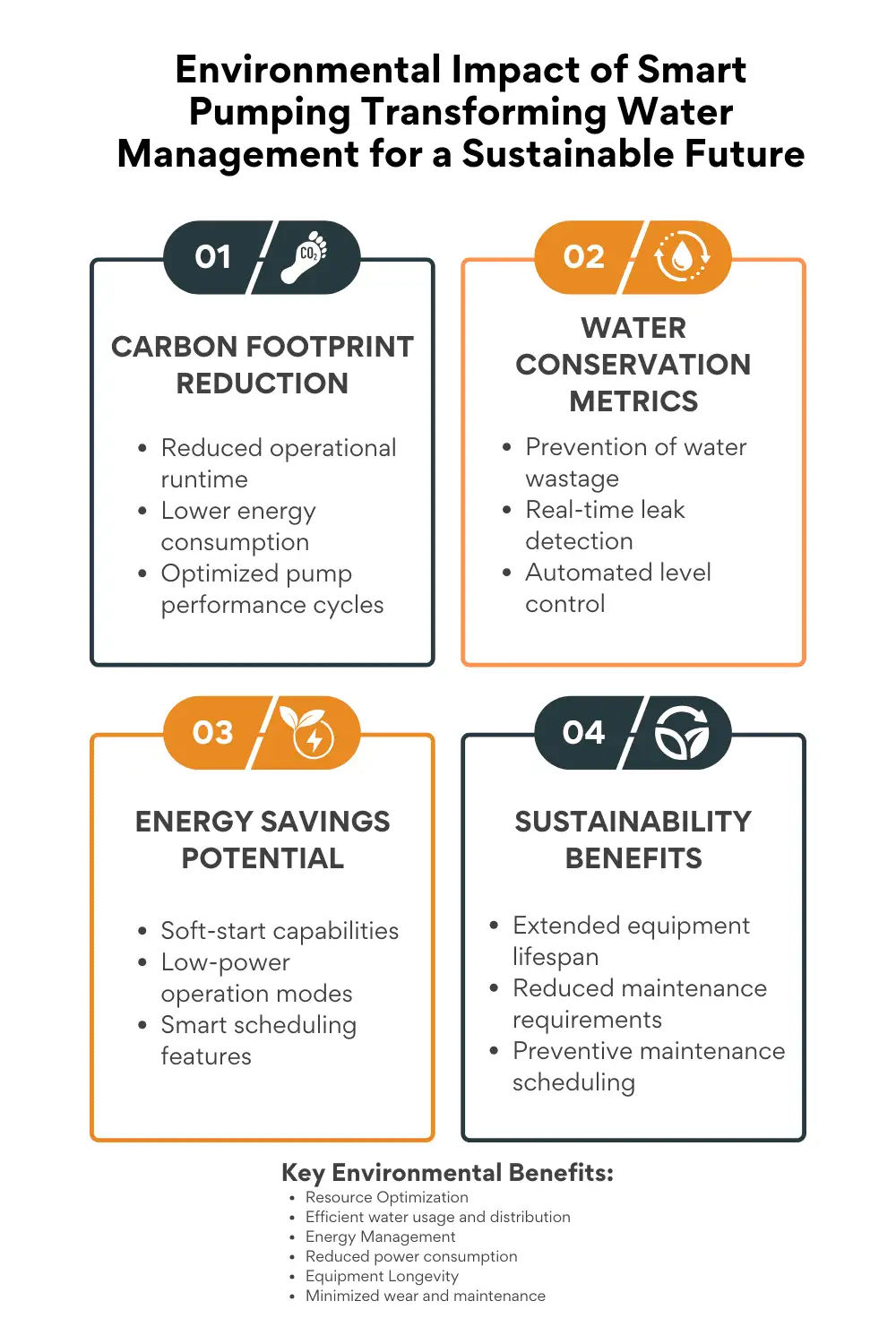

6. Energy Efficiency Features

When choosing a pump controller, look for one with energy-efficient features to lessen operational costs. Features such as soft-start capabilities and low-power modes, to name a few, can help minimise the electricity required to operate the pump. These energy-efficient functionalities can also reduce wear on pump components, thus extending the lifespan of the equipment and saving you repair costs.

7. Customisable Control Parameters

Different operations will have different water requirements. Thus, having a pump controller with fully customisable parameters – such as adjustable thresholds for water levels, pressure settings, and flow rates – ensures that you can fine-tune your pumps to meet your project’s specific needs. This flexibility also allows for quick adjustments should any change occur in your site’s conditions, increasing the adaptability of your pumps.

Conclusion

Investing in a quality pump controller can significantly increase the efficiency of your project’s resource management, reduce operational costs, and enhance the security of your water system. So, make sure that the one you’ll be getting has most if not all of the features discussed above so that you can guarantee the best possible outcome for your site’s water resource management.